Use less energy to manufacture/ship?

Use 100% recycled content?

Reduce raw materials?

Design for circularity?

States, countries and retailers may have guidelines or legislation that impacts your packaging.

Will your product be sold via e-commerce?

Certain materials withstand shipping conditions better than others.

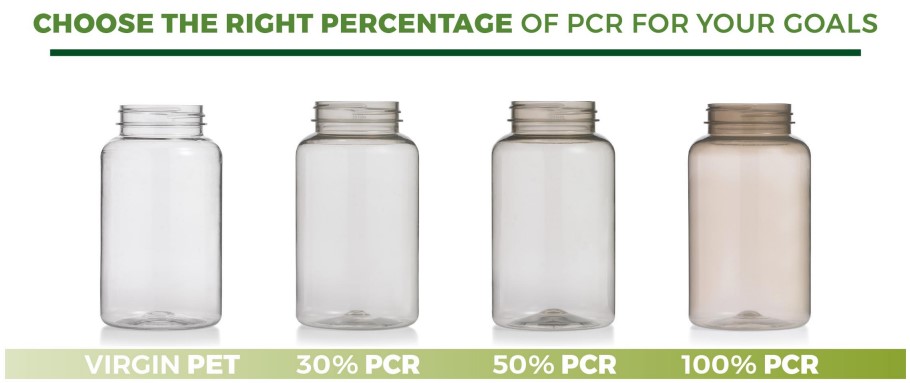

Post-consumer resin (PCR) is a great way to reduce the carbon footprint of your packaging.

Pretium offers standard percentages of 30%, 50% and 100% PCR and includes PCR pricing options on every quote.

We also offer Prevented Ocean PlasticTM certified ocean-bound PCR.

PET and HDPE resins are the most commonly-recycled resins in the US.

We can help you navigate the APR Design Guide to make packaging decisions that maximize opportunities for recyclability.

Life Cycle Assessments (LCAs) help brands understand how their packaging impacts the environment.

With tools like Compass software, Pretium can perform LCAs on a variety of packages.

Light-weighted containers use less plastic without sacrificing quality.

Sustainability is in the DNA of Pretium's Proud Brands

All the packaging we make has three primary goals, and the goals are no different for the sustainable solutions we offer:

Give consumers a convenient way to purchase,

transport and store the product

Maintain the safety of your products and

health of your customers

Appeal to consumers through functional or

aesthetic advantages over competing brands

There are four primary types of sustainable packaging that

Pretium is known for that perform in these three areas:

100% Recycled Content

Pretium is one of the only companies that makes bottles and jars with up to 100% post-consumer resin (PCR) in clear and colors, and we’ve been doing it the longest. We use recycled HDPE and PET resins that come with an FDA Letter of Non-Objection that allows the post-consumer resins to be used for food and pharmaceutical packaging, and which provides the brand owner with a sustainable packaging solution that performs just like the plastics they are using now. While most PCR bottles require a 50,000-piece MOQ, we do carry inventory of 100% PCR bottles in some of our most popular styles which can be purchased by the pallet.

Recyclable Resins

You may have noticed a lot of brands are using the phrase “recycle-ready” when they talk about their packaging. This means the packaging they have selected is accepted by most community recycling programs and has a viable recycling stream that can capture the resin and give it a useful second life. Ninety-eight per cent of the plastic bottles Pretium makes are mono-layer PET or HDPE plastic, which are SPI codes 1 and 2 respectively, and are the most widely recycled plastics in the world. (And, beyond just your bottle choice, we can also recommend decorating processes such as direct screen printing with UV inks that maintain the highest degree of recyclability for your finished package.)

Lightweighting

Ultimately, the goal of every brand owner should be to minimize packaging as much as possible while making sure their products are protected. Light-weighting the primary package – in our case, a plastic bottle or jar – is one very good way to reduce the amount of raw materials being consumed for each package while still delivering a safe product to the consumer. Pretium’s Design & Engineering teams work with customers to find the optimal gram weight that balances performance and the environment. We’re also using the resources in our Design Center and Innovation Lab to execute internal projects to evaluate the gram weights of our stock product lines and make them lighter-weight. Some projects we’ve done have taken up to 21% of the total gram weight of the bottle with no negative effect on its performance.

Order Samples

Pretium has a limited number of sample bottles made from post-consumer (recycled) resins and plant-based resins. You may order one sample of the options we have in our sample room.

The options for sustainable packaging and manufacturing are constantly evolving, and Pretium Packaging is committed to staying on top of the solutions that make the most sense for our customers. To learn more about which different sustainable materials might be right for your business, reference our Plastics Comparison Chart.

To sample our line of sustainable bottles and jars, browse our online catalog or connect with your Pretium Key Account Manager today.

Sustainability FAQs

Most of Pretium’s sustainable packaging options fall into one of four categories:

-

- recyclable resins (PET and HDPE)

- post-consumer (recycled) resins (PET and HDPE)

- Certified Ocean Bound PCR

- lightweighted packages that reduce gram weight while retaining performance

We work with you to evaluate all of the options to find the sustainable solution that meets your requirements.

Sustainable options such as post-consumer resins, bioresins and biodegradable additives typically require a 50,000 piece minimum and may also require a set-up fee or purge charge depending on the manufacturing process and bottle size.

We do not manufacture bottles from plastic that has been collected from the ocean, but we do have reliable sources of post-consumer resin made from bottles that were prevented from entering the ocean. Our preferred partner for this Certified Ocean Bound PCR is Prevented Ocean PlasticTM. Like all resins used in Pretium’s manufacturing processes, our Certified Ocean Bound PCR carries a letter of non-objection from the FDA and is safe for food contact. If you are interested in these resins, please specify “Ocean Bound” when you ask for a quote, as the resin is more expensive than PCR collected from traditional sources.

Upcharges for PCR fluctuate widely based on market conditions and the source of the PCR. Because we use only food-safe resins approved by the FDA, recycled PET is typically 10% to 20% more than virgin PET and recycled HDPE can be 40% to 50% higher than virgin HDPE. Certified Ocean Bound PCR has a greater upcharge and must be quoted based on current market conditions. All written quotations from Pretium include a second quote for 30% PCR as an option.

The post-consumer resins Pretium uses all come with FDA letters of non-objection and are safe for food contact. To obtain that designation, the resin must be collected, sorted, cleaned, ground, melted, recrystallized and/or repelletized all according to processes approved by the FDA. There are very few companies that are equipped to put post-consumer bottles through this rigorous process, so there is a premium for the high-quality post-consumer resin they produce. Our Certified Ocean Bound PCR is also covered by an FDA LNO.

That depends on your product and any certifications you require. Most products probably do not need to undergo stability testing because the post-consumer versions of PCR and HDPE are very similar to virgin and have similar performance. But if you have FDA filings or other pharma or OTC requirements, we would recommend that you conduct stability testing. Stability testing is the responsiblity of the customer.

Yes, because the cost of PCR resin is typically higher than virgin resin, the amount of PCR you incorporate in your packaging is directly related to the final price. As a convenience to customers, Pretium includes a quote for 30% PCR on every written quotation so you can see how the inclusion of PCR impacts the bottle price. Pretium uses IHS as the benchmark for PCR price fluctuations.

Because of the manufacturing processes and blending equipment we have, our standard percentages of PCR are:

Single-stage PET: 30%, 50% or 100%

2-stage PET: 30%, 50% or 100% (testing required before we can commit to 100% for this process)

HDPE: 30%, 50% or 100%

Pretium can run 100% PCR in all of our single-stage PET items, all of our EBM and IBM HDPE items, and most 2-stage PET items.

Whether you are running PCR in clear, white, translucents, tints or opaque colors, there is always a chance for color variation from lot to lot – particularly with lighter colors. For this reason, we request that every customer buying PCR bottles sign a waiver agreeing to accept reasonable variations in the final color and clarity.

At this time, there is not FDA approval for post-consumer resins (PCR). In lieu of approval, the FDA issues an FDA Letter of Non-Objection which certifies that the collection, cleaning, and processing of the post-consumer materials meets their standards for food-safe plastics.