What About the Numbers?

The first number represents the outer diameter (in mm) of the neck opening. The second number refers to the thread configuration and height of the neck. To see some of our most common narrow-neck finish dimensions, click on the numbers below:

What About the Letters?

When you receive technical drawings of our bottles and jars, the closure area will have several dimensions listed to help you know more about the tolerances of a particular bottle’s neck. To learn more about these important specifications, click on the letters below:

Special Necks, Including Pretium’s HDPE Straight Sided Canister Line

In addition to the Continuous Thread and J-Cap necks on the majority of our bottles, Pretium makes some stock bottles with special neck finishes.

For example, our HDPE Straight Sided Canister Line offers 11 bottles, each with three different 120mm neck finishes. Here’s what you need to know before ordering these bottles:

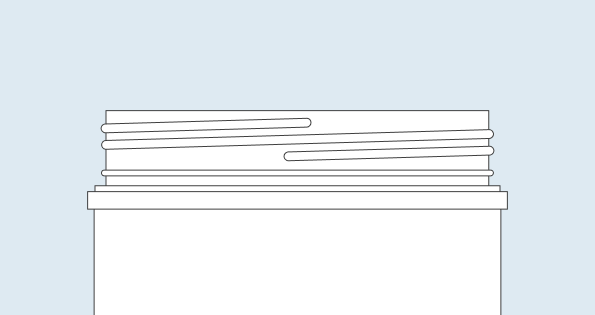

Pretium's 120-400 Continuous Thread neck fits Deep-Skirt CT closures

Customers who want to use a 120-400 Deep Skirt Continuous Thread closure will prefer this new neck finish, which eliminates the visual gap between the Deep Skirt closure and the large ring at the top of the canister. Deep Skirt closures from Innovative Molding work very well with this new neck finish which features two full thread turns.

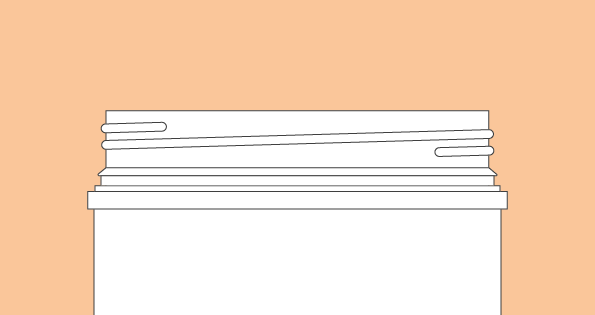

120 Pano/Continuous Thread neck is ideal when you need a Tamper Evident closure

If you need a tamper-evident closure, you should order the 120-400 Pano/CT neck style which features a shrink bead to accommodate the Pano tear-strip closure. For information on Pano closures visit www.panocap.com. Traditional continuous thread closures will sit high on the bottle, so the bead beneath the threads may be exposed. To ensure proper fit of a 120-400 CT closure, we recommend that you purchase lined closures. Phoenix Closures Item #120-DCT-74 is a Continuous Thread option that works with this 1-3/4 turn thread configuration.

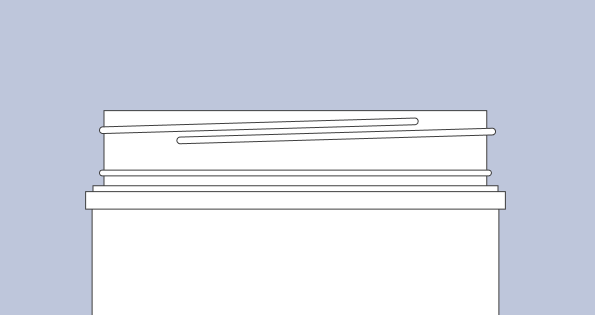

Triple Lead Short (TLS) neck fits a Deep-Skirt closure from Sho-Me Container

Pretium developed the “Triple Lead Short” (TLS) neck finish to accommodate customers who already have 120mm deep skirt closures from Sho-Me Container or Priority Plastics. The Triple Lead thread design engages the closure threads at three separate points.

We call this the Triple Lead Short because the threads have a short “S” dimension (the distance from the top of the threads to the top of the bottle).